01

Metal Injection Molding Service Custom Injection Molding Service

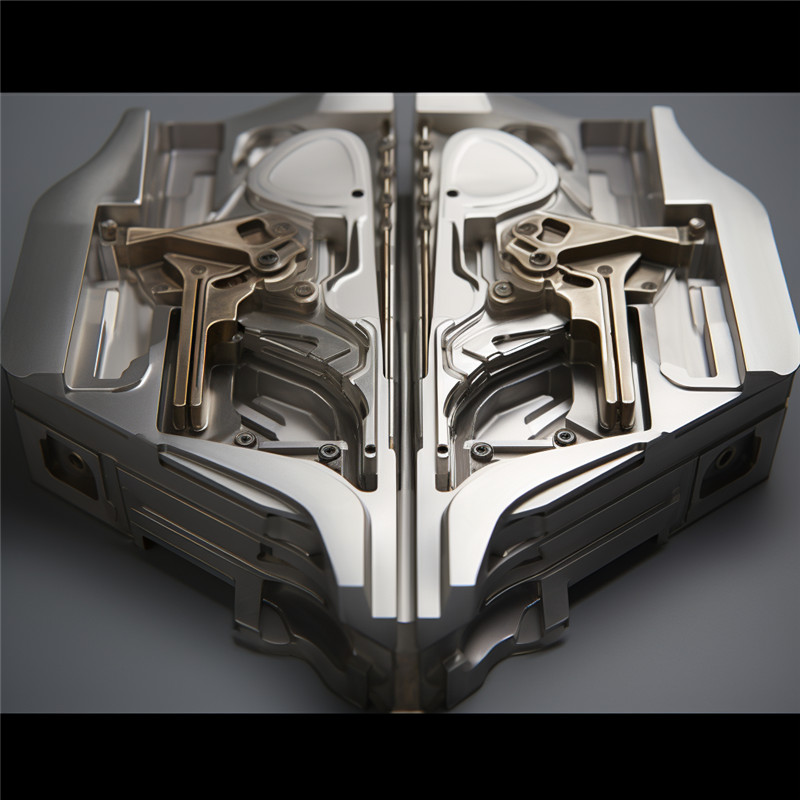

Our Metal Injection Molding Service

By utilizing Bushang’s Metal Injection Molding (MIM) solutions in China, we have the capability to shape metal parts based on their size, intricacy, and volume requirements. Our MIM process allows us to produce high-quality metal parts with complex geometries and tight tolerances. Whether you need small, intricate components or larger parts, our MIM solutions can cater to your specific needs. With our expertise in MIM technology, we can provide efficient and cost-effective solutions for your metal part production.

Custom Metal Injection Molding Solutions

1、Rapid Prototyping

Take advantage of our rapid injection molding services, allowing you to quickly obtain 1K-100K units at a low cost. With the use of aluminum or steel molds, we guarantee fast turnaround times, directly addressing your production challenges and reducing time-to-market. Our efficient injection molding process ensures high-quality results while maintaining cost-effectiveness. Trust us to deliver the quantities you need, promptly and affordably, helping you meet your production goals efficiently.

2、Low Volume Production

Our low volume injection molding services are intended to increase your production output by enabling you to use durable steel molds to produce 100K–1M units. This methodology guarantees superior quality and uniformity during the entire production process, efficiently meeting your requirement for large-scale, accurate production runs. With our knowledge and cutting-edge tools, we can fulfill your needs while upholding the highest standards. You can rely on us to provide you with dependable and effective low volume injection molding solutions that help you achieve your production objectives.

Metal Injection Molding Application

Metal injection molding (MIM) is a versatile manufacturing process that finds applications across various industries. Here are some common examples:

Medical and Dental Devices:

1.Surgical instruments

2.Orthodontic brackets

3.Dental implants

Aerospace and Defense:

1.1Small complex aerospace components

2.Missile and munition components

3.Firearm components

Automotive:

1.Engine and transmission parts

2.Fuel system components

3.Sensors and actuators

Electronics:

1.Connectors and terminals

2.EMI shielding components

3.Miniature switches

Consumer Goods:

1.Watch components

2.Lock and key components

3.Precision hinges and clasps

Industrial Equipment:

1.Valves and fittings

2.Pump components

3.Gears and gearboxes

Textile Machinery:

1.Nozzles and guide pins

2.Needle holders

3.Spinnerets for fiber production

Energy and Power Generation:

1.Turbine blades and nozzles

2.Heat exchanger components

3.Electrical connectors and contacts

Telecommunications:

1.Antenna components

2.Connector housings

3.Waveguide components

Fire Sprinkler Systems:

1.Sprinkler heads

2.Valve components

These examples represent just a fraction of the potential applications for metal injection molding. As technology advances and the demand for high-precision, complex metal parts increases, MIM continues to expand into new industries. Its ability to produce intricate geometries and tight tolerances while minimizing material waste makes it an attractive choice in industries where traditional manufacturing methods may be less cost-effective or practical.

Metal Injection Molding Service Materials

Metal Injection Molding (MIM) offers a wide range of metal materials and alloys for use in the manufacturing process. Some common materials used in MIM include:

Aluminum Alloys: Aluminum 6061, Aluminum 7075

Stainless Steel Alloys: 316L Stainless Steel, 17-4 PH Stainless Steel, 440C Stainless Steel, 304 Stainless Steel

Tool Steels: M2 Tool Steel, D2 Tool Steel, A2 Tool Steel

Carbon Steel Alloys: 1018 Carbon Steel, 1045 Carbon Steel, 1095 Carbon Steel

Low Alloy Steels: 4140 Low Alloy Steel, 8620 Low Alloy Steel

High-Speed Steels: M42 High-Speed Steel, M4 High-Speed Steel

Copper Alloys: Copper-Tin Alloys, Copper-Nickel Alloys

Titanium Alloys: Ti-6Al-4V (Grade 5), Ti-6Al-7Nb

Tungsten Alloys: Tungsten-Nickel-Copper Alloys

Precious Metal Alloys: Gold Alloys, Silver Alloys

Magnetic Alloys: Soft Magnetic Alloys (e.g., 49%Ni-Fe)

Cobalt Alloys: Cobalt-Chromium Alloys (e.g., CoCrMo)

Iron Alloys: Sintered Iron, Soft Magnetic Iron, Ductile Iron

Carbide Materials: Tungsten Carbide (WC), Cemented Carbide

Cermet Materials: Titanium Carbide (TiC) Cermet, Chromium Carbide (Cr3C2) Cermet

These materials offer a wide range of properties and characteristics, allowing for the production of diverse and high-quality metal parts through the MIM process.