01

Professional High Precision Plastic Injection Moulding Plastic Prototyping with 3D Drawings

Our Plastic Injection Moding Servers

The Decision to Prototype:

After meticulously illustrating a custom plastic part and seemingly reaching the brink of production readiness, opting for prototype injection molding becomes a strategic consideration. This preemptive step offers a proactive approach to:

Identifying Refinements: Uncover design nuances and potential improvements that may not be evident on paper.

Mitigating Risks: Proactively address challenges and uncertainties before committing to large-scale production.

Ensuring Precision: Fine-tune the production process for optimal precision and efficiency.

In conclusion, injection molding prototyping technology is not merely a step in the manufacturing journey; it is a strategic imperative. It empowers designers and manufacturers to navigate the intricacies of product development with agility, foresight, and cost-effectiveness, laying the foundation for successful and streamlined mass production.

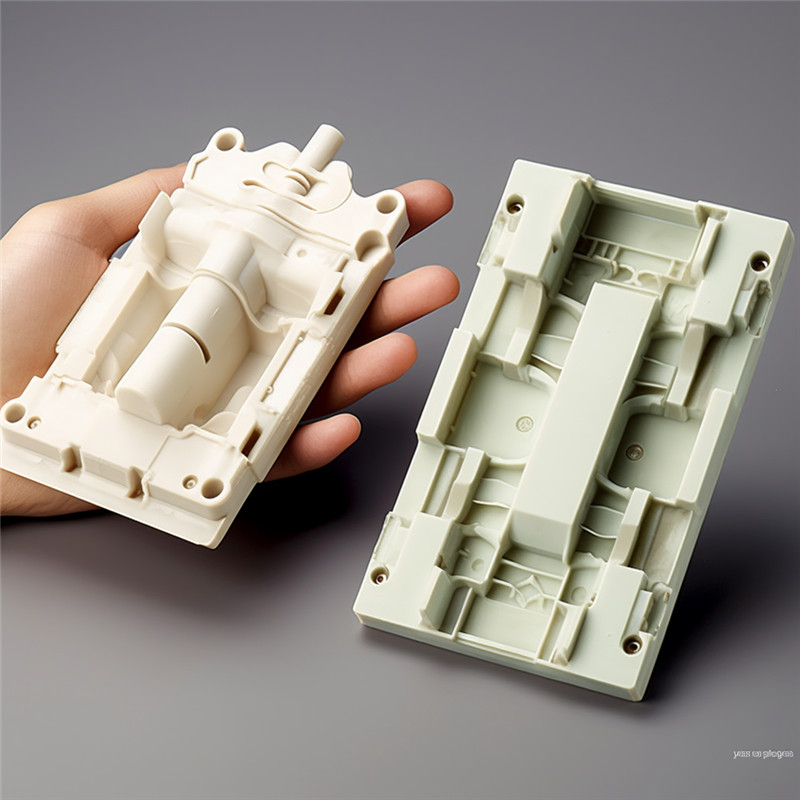

Gallery of Injection Molding Prototyping

CNC Machining Materials

Injection Molding Prototyping Materials

Choosing the Right Materials for Injection Molding Prototyping

Selecting the appropriate material for injection molding prototyping is a pivotal decision in the product development process. The choice hinges on factors such as project requirements, budget constraints, and the specific characteristics essential for the prototype. Alignment with the intended function, performance requirements, and the anticipated conditions the prototype will face is paramount. Injection molding prototyping offers a diverse array of materials, empowering designers and engineers to craft prototypes that faithfully mimic the properties of the intended final product. Additionally, considerations such as cost, lead time, and ease of machining or finishing play a crucial role in material selection.

Thermoplastics:

ABS (Acrylonitrile Butadiene Styrene):

Properties: Known for strength and impact resistance.

Applications: Commonly used for prototyping consumer products and automotive components.

Polypropylene:

Properties: Lightweight, chemical-resistant.

Applications: Suitable for packaging, containers, and automotive parts.

Polyethylene:

Forms: HDPE (High-Density Polyethylene), LDPE (Low-Density Polyethylene).

Applications: Used for products ranging from bottles to toys.

Polycarbonate:

Properties: High impact resistance, optical clarity.

Applications: Ideal for prototypes of optical lenses, electronics, and safety gear.

Engineering Plastics:

Nylon (Polyamide):

Properties: Strong, durable, good wear resistance.

Applications: Used for prototypes of gears, bearings, and structural components.

Polyoxymethylene (POM):

Also Known As: Acetal.

Properties: Tough and rigid.

Applications: Used for prototypes of mechanical parts like gears and bushings.

PEEK (Polyether Ether Ketone):

Properties: High-performance, excellent chemical resistance.

Applications: Suitable for prototypes in demanding environments, such as aerospace and medical.

Elastomers:

Silicone Rubber:

Properties: Flexible, resistant to extreme temperatures.

Applications: Used for prototypes of medical devices, seals, and consumer products.

Bioplastics:

PLA (Polylactic Acid):

Properties: Biodegradable.

Applications: Used in environmentally friendly prototypes, often chosen for packaging and consumer goods.

In the realm of injection molding prototyping, the choice of materials is a nuanced decision that requires careful consideration of both technical and practical aspects. Each material brings its unique set of properties, contributing to the precision and functionality of the prototype.

Gallery of Injection Molding Prototyping